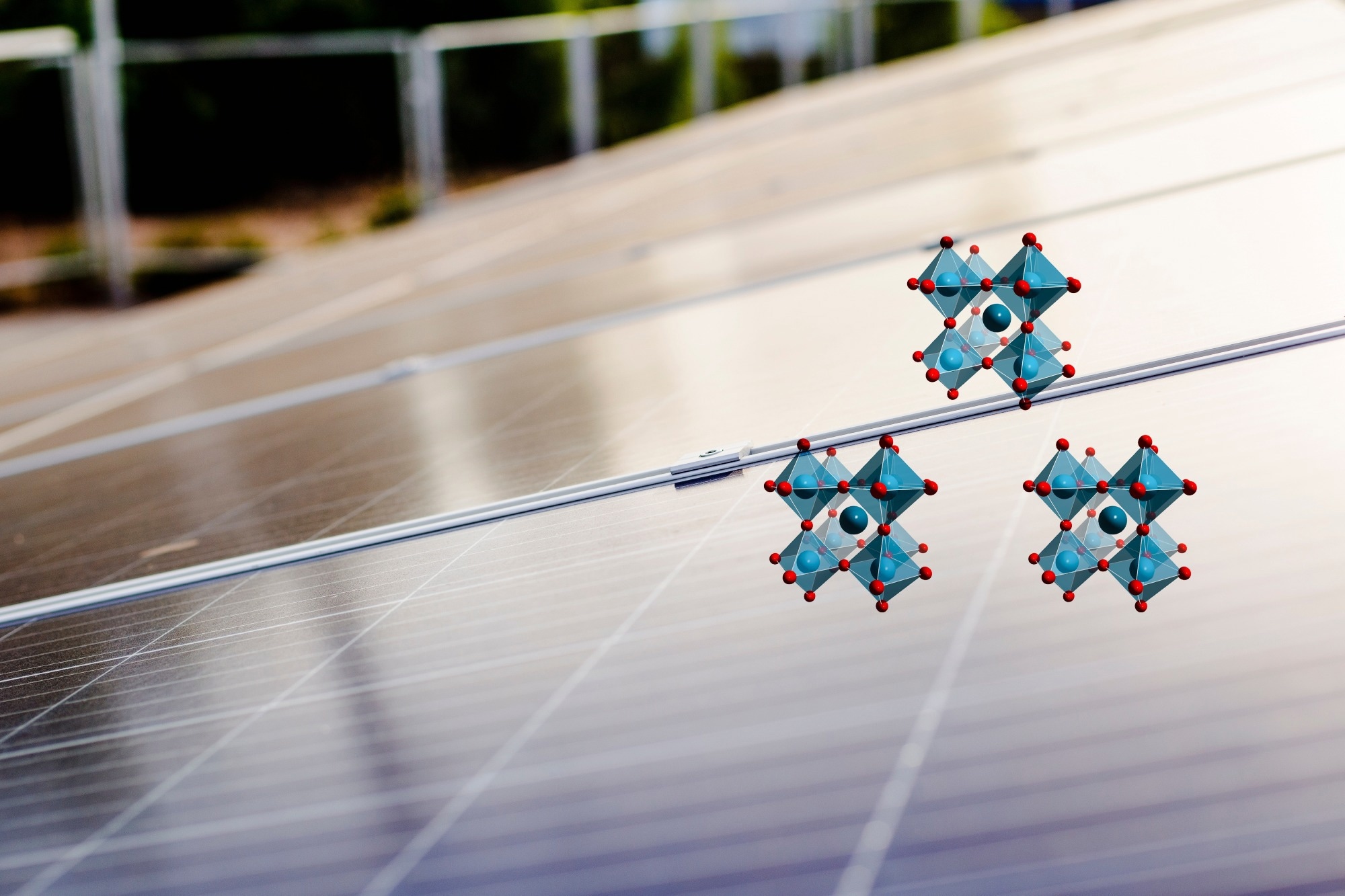

By combining AI-driven reverse engineering with eco-friendly solvents, scientists are redefining the future of perovskite solar cells, delivering affordable, low-carbon energy for global deployment.

Image Credit: Kewiko / Shutterstock

AI-Driven Roadmap for Sustainable Solar Cells

What if we could generate clean electricity more affordably while protecting the environment at the same time? A team of researchers in Korea has presented a roadmap for sustainable solar cells that integrates AI technology to bring this future closer. This achievement marks a new milestone in the transition to green energy and has been selected as the cover of the online edition of the international academic journal Green Chemistry.

Perovskite Solar Cells: Opportunities and Challenges

Solar power is a prominent sustainable energy source that can reduce carbon emissions. In particular, perovskite solar cells, also known as "next-generation solar cells," have received attention for their high theoretical efficiency (34%), which surpasses that of traditional silicon solar cells. However, the production of these cells requires the use of toxic chemicals and has limited long-term stability, hindering their commercialization.

Research Collaboration and New Process

POSTECH (Pohang University of Science and Technology) Department of Chemical Engineering, led by Professor Jeehoon Han, collaborated with the Department of Chemical Engineering at the University of Seoul, led by Professor Min Kim, to solve the problem. The research team developed a new manufacturing process that utilizes bio-based solvents, such as GVL and EA, in place of the toxic solvent DMF.

AI-Powered Reverse Engineering

The study's core is based on AI-driven reverse engineering technology. By analyzing experimental data, the research team identified optimal conditions to boost efficiency while minimizing costs and carbon emissions. They then verified the conditions proposed by AI through actual experiments. They presented a sustainability evaluation model that considers manufacturing costs, environmental impact, and process efficiency, as well as a global deployment scenario.

Key Outcomes

The GVL-EA process developed by the research team reduces the manufacturing cost of perovskite solar cells by half and decreases the climate impact by over 80%. Additionally, they confirmed that considering module lifespan and recycling strategies together can help identify the actual break-even point for commercialization in different regions.

Expert Insights

POSTECH's Professor Jeehoon Han said, "AI has found conditions that were previously considered impossible by optimizing the process itself." He added that using non-toxic bio-solvents can make solar cells safer, cheaper, and more efficient.

Funding

This study was supported by the Ministry of Science and ICT's "Program of Development of Eco-friendly Chemicals as Alternative Raw Materials to Oil," the National Research Foundation of Korea's "New Faculty Research Support Program," and the "Doctoral Student Research Support Program."

Source:

Journal reference: