Researchers from The Grainger College of Engineering have combined deep metallurgical expertise with advanced machine learning to generate detailed spatial maps of alloy microstructures, paving the way for faster and more accurate autonomous material design.

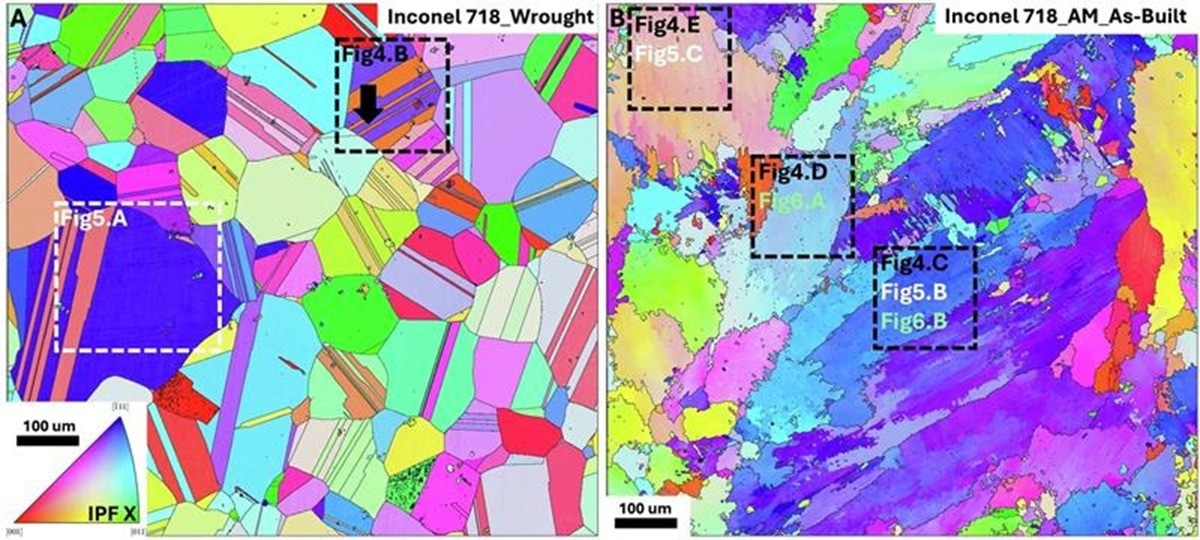

Electron backscatter diffraction (EBSD) maps of the investigated Inconel 718 alloys. Inverse pole figure (IPF) maps along the X direction (horizontal) are presented for a A wrought and fully recrystallized 718 alloy, and a B additively manufactured as-built 718 alloy. Image Credit: Grainger College of Engineering

From Human Fingerprints to Material Fingerprints

Just as no two human fingerprints are identical, metal alloys also possess unique “fingerprints” determined by the spatial arrangement of their microstructural features. These microscopic patterns strongly influence properties such as strength, fatigue life, and resistance to extreme conditions. Traditional analysis methods, however, compress this complexity into a few averaged descriptors, losing vital information.

Engineers at Illinois are tackling this limitation. In a recent set of papers from the lab of Jean-Charles Stinville, assistant professor of materials science and engineering, researchers introduced new machine learning tools capable of directly capturing and interpreting these intricate spatial patterns.

Microstructures Under Extreme Demands

Microstructures govern how metals behave under load, temperature, and environmental stress. For aerospace and space applications, alloys must maintain mechanical integrity at extreme temperatures. Conventional alloys often degrade under these conditions, and identifying new compositions that withstand harsh environments remains a significant challenge.

“We are sending these materials into increasingly extreme environments,” Stinville said. “We want to find new ways to accelerate the identification of alloy chemistries and microstructures that can withstand these harsh conditions.”

Material Spatial Intelligence: Capturing Heterogeneity

To capture the full richness of alloy microstructures, Stinville’s team applied deep learning to electron diffraction patterns. Instead of collapsing the data into simple averages, the model encodes spatial and structural information into a latent representation that preserves microstructural heterogeneities. Stinville refers to this framework as Material Spatial Intelligence.

Published in NPJ Computational Materials, the team’s first model successfully distinguished alloy microstructures at unprecedented resolution. A follow-up study in Scripta Materialia demonstrated that this same spatial intelligence could accelerate the prediction of mechanical properties, achieving improvements by orders of magnitude.

Predicting Material Behavior from Deformation Fingerprints

By combining alloy characterization with high-resolution digital image correlation, the researchers measured how microscopic regions of metals deform. They then trained a machine learning model to recognize these deformation “fingerprints,” enabling rapid prediction of properties such as:

- strength

- fatigue life

- ductility

This significantly reduces testing time and enables faster, more precise evaluation of new alloys.

Toward Autonomous Alloy Design

Stinville envisions a future “inverse design” tool in which users specify desired properties and the system proposes compatible alloy chemistries and microstructures. Integrating these models with automated characterization systems will bring the field closer to fully autonomous alloy design.

“This approach unites our field’s fundamental understanding of metals with new and efficient AI database tools,” Stinville said. “We’re integrating the present with the past.”

A Collaborative Effort

Significant contributions to this research were made by Mathieu Calvat, Chris Bean, and Dhruv Anjaria.

Source:

Journal references:

- Calvat, M., Bean, C., Anjaria, D., Park, H., Wang, H., Vecchio, K., & Stinville, J. C. (2025). Learning metal microstructural heterogeneity through spatial mapping of diffraction latent space features. Npj Computational Materials, 11(1), 284. DOI: 10.1038/s41524-025-01770-8, https://www.nature.com/articles/s41524-025-01770-8

- Calvat, M., Bean, C., Anjaria, D., Wang, H., Vecchio, K., & Stinville, J. (2026). Plasticity encoding and mapping during elementary loading for accelerated mechanical properties prediction. Scripta Materialia, 273, 117082. DOI:10.1016/j.scriptamat.2025.117082, https://www.sciencedirect.com/science/article/abs/pii/S1359646225005433