A team from Tokyo University of Science has unveiled an AI-powered X-ray analysis method that deciphers the complex spectral fingerprints of materials with high precision, paving the way for faster, automated material discovery and sustainable technological innovation.

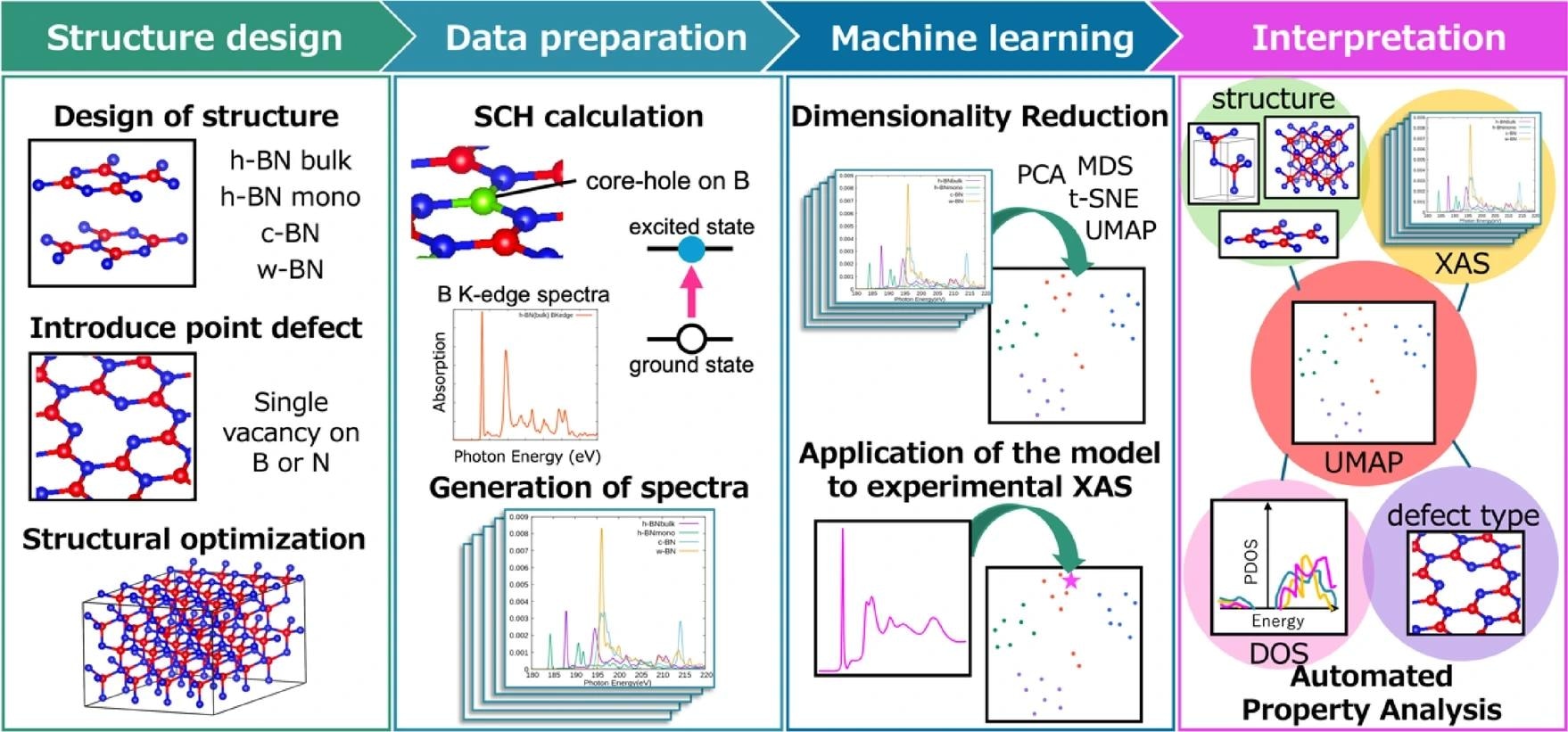

Workflow of the present study. Initially, structural optimization was performed for various BN systems, and high-dimensional XAS spectra along with DOS spectra were generated using SCH calculations. Subsequently, unsupervised machine learning techniques were employed to reduce the XAS spectra to a low-dimensional space, thereby extracting the intrinsic information contained within the high-dimensional data. The clustering results were then analyzed to elucidate the relationships among the XAS spectra, crystal structures, electronic states, and atomic defects. Finally, experimental data were projected into the low-dimensional space to explore the potential for integrated computational and experimental material identification.

Understanding the properties of different materials is an important step in material design. X-ray absorption spectroscopy (XAS) is a crucial technique for this purpose, as it provides detailed insights into a material's composition, structure, and functional characteristics. The technique works by directing a beam of high-energy X-rays at a sample and recording how X-rays of different energy levels are absorbed. Similar to how white light splits into a rainbow after passing through a prism, XAS produces a spectrum of X-rays with different energies. This spectrum is called spectral data, which acts like a unique fingerprint of a material, helping scientists identify the elements present in the material and see how the atoms are arranged. This information, known as the 'electronic state,' determines the functional properties of materials.

Challenges in analyzing boron-based materials

Boron compounds have significant applications in semiconductors, Internet-of-Things (IoT) devices, and energy storage. In these materials, atomic modifications, structural defects, impurities, and doped elements each produce unique, complex variations in spectral data. Detailed analyses of these variations provide key insights into their electronic state and are crucial for rational material design. Traditionally, however, such analyses required extensive expertise and manual labor, especially when large datasets have to be examined visually.

The lack of prior reference data and the subjectivity of interpretations made the task even more difficult. Developing an automated approach that can establish a clear and objective link between XAS data and the underlying material properties has been a longstanding challenge.

Tokyo University of Science develops AI-based XAS analysis

Now, a research team headed by Professor Masato Kotsugi from the Department of Material Science and Technology at Tokyo University of Science (TUS), Japan, has taken a promising step towards this goal. Together, Ms. Reika Hasegawa and Dr. Arpita Varadwaj, both from TUS and who led the study, developed an automated artificial intelligence (AI)-based approach for analyzing XAS data. "AI-based data-driven methods, such as machine learning, can be powerful tools for efficiently analyzing and interpreting measurement data, providing objective insights," explains Prof. Kotsugi. The study was published in the journal Scientific Reports on 10 November 2025.

Generating and validating XAS data for boron nitride

The team first generated XAS data for three different phases of boron nitride (BN) with different atomic structures, along with their defect analogues. The XAS data were generated using theoretical calculations based on fundamental physics and validated using experimental data.

Machine learning enables dimensionality reduction in spectral analysis

To analyze this data, the team employed machine learning techniques that use dimensionality reduction. In this method, highly complex data with many variables is reduced to its fundamental elements, capturing only its essential features. In XAS, where a dataset can have thousands of variables, machine learning helps scientists focus on patterns that truly reflect the materials' electronic states. As Prof. Kotsugi explains, "The underlying physics in XAS data can be explained by only a few mathematical calculations." The team tested four machine learning methods: Principal Component Analysis (PCA), Multidimensional Scaling (MDS), t-distributed Stochastic Neighbor Embedding (t-SNE), and Uniform Manifold Approximation and Projection (UMAP).

UMAP achieves high accuracy and robustness

Among these methods, UMAP performed exceptionally well in classifying complex spectral data according to different atomic structures and defects. It was able not only to identify global trends but also to detect subtle differences between phases and types of defects. To confirm its validity, the researchers compared these results with experimental XAS data, which closely matched the classifications derived by UMAP, despite the presence of noise and variability. This demonstrates that the method is robust against noise and variations introduced by experimental conditions. "Our findings show that UMAP can be a valuable tool for rapid, scalable, automated, and importantly, objective material identification using complex experimental spectral data," remarks Prof. Kotsugi.

Advancing beyond statistical approaches

Notably, this study represents a more advanced method compared to the team's previous statistical similarity-based approach. While that method was accurate, this new AI-based method exhibits even higher accuracy and can also reveal meaningful variations in electronic states.

Applications in data-driven material design

Highlighting the study's impact, Prof. Kotsugi says, "Our method demonstrates the potential of autonomous structural identification, opening up new possibilities for data-driven material design and development of novel materials." The AI-based approach has already been applied to different experimental datasets. In the near future, this approach will be implemented as software at the Nano-Terasu synchrotron radiation center. Looking ahead, this innovative AI-based approach will accelerate the development of new materials, advancing key fields like semiconductors, catalysis, and energy storage, helping to build a more sustainable future.

About Professor Masato Kotsugi

Professor Masato Kotsugi graduated from Sophia University, Japan, in 1996 and subsequently received his Ph.D. from the Graduate School of Engineering Science at Osaka University, Japan, in 2001. He joined Tokyo University of Science in 2015 as a lecturer and is now a Professor at the Faculty of Advanced Engineering, Department of Materials Science and Technology. Prof. Kotsugi and his students conduct cutting-edge research on high-performance materials to create a green-energy society. He has published over 130 peer-reviewed papers and is currently interested in solid-state physics, magnetism, synchrotron radiation, and materials informatics.

Funding acknowledgment

The team would like to thank the Institute of Molecular Science, Okazaki, Japan, for the supercomputing facilities received for calculations (Project: 23-IMS-C137), and all authors thank the CREST project for generous funding (JPMJCR21O4).

Source:

Journal reference:

- Hasegawa, R., Varadwaj, A., Foggiatto, A. L., Niibe, M., Yamazaki, T., Horio, M., Ando, Y., Kondo, T., Matsuda, I., & Kotsugi, M. (2025). Automated elucidation of crystal and electronic structures in boron nitride from X-ray absorption spectra using uniform manifold approximation and projection. Scientific Reports, 15(1), 1-12. DOI: 10.1038/s41598-025-18580-z, https://www.nature.com/articles/s41598-025-18580-z